GMP and Food Safety Services for Your Food Contact Materials

Ensuring safety, compliance, and consumer trust – from product design to market launch.

When it comes to food contact materials (FCMs), safety isn’t optional. Every stage — from design to manufacturing to post-production — carries potential risks that can impact consumers and damage your brand.

At TÜV Rheinland, we help you find and control food safety risks in your product design, production processes, and manufacturing sites.

To keep food contact materials (FCMs) safe, manufacturers should:

- Design with hygiene in mind – supported by an HACCP (Hazard Analysis and Critical Control Points) study.

- Apply Good Manufacturing Practices (GMP) – backed by a food safety risk assessment.

- Test and monitor products regularly – using microbiological testing to ensure safety and compliance.

Our international network of qualified food safety experts provides training, document reviews, and on-site audits to help you meet these requirements with confidence.

Let’s make your products safer — contact us today!

Why Hygienic Design Matters

Food safety risks can arise at many points in product development. That’s why a hygienic design combined with an HACCP (Hazard Analysis and Critical Control Points) study is essential. These steps help identify Critical Control Points (CCPs) early on, preventing safety issues before they occur.

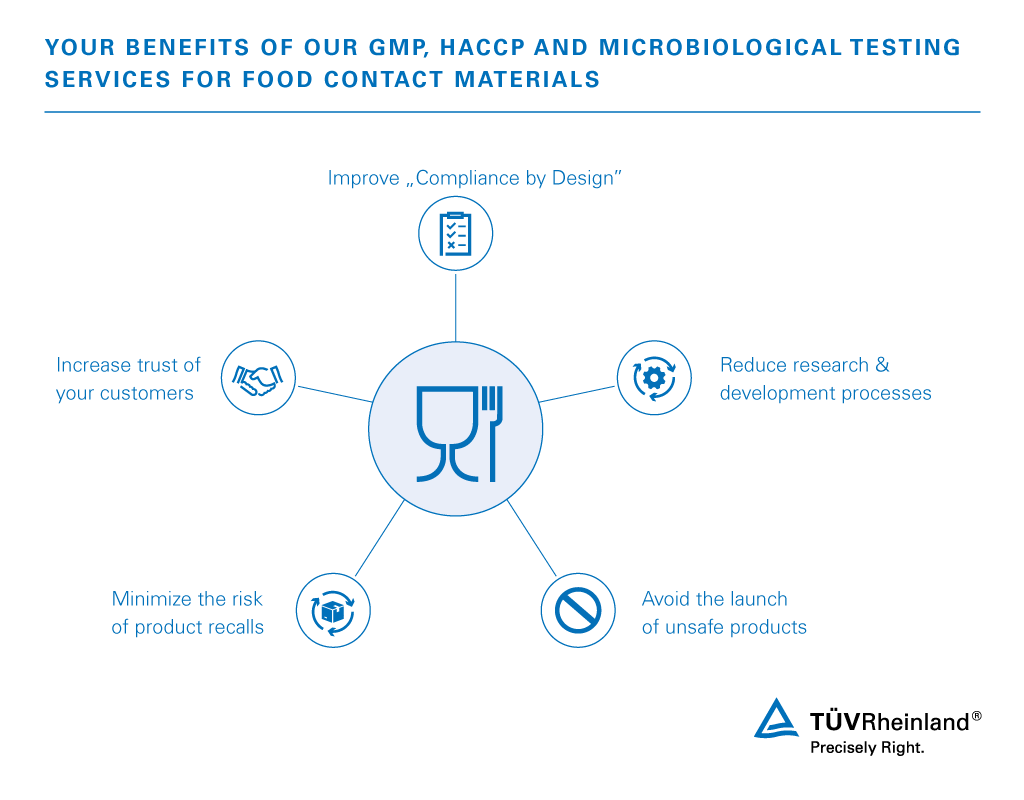

Compliance by Design

Our experts can assess your product design during development to:

- Reduce R&D time and costs

- Avoid unsafe product launches

- Lower the risk of recalls

- Strengthen your “Compliance by Design” approach

Managing Risks in Manufacturing

During production, microbiological, physical, and chemical hazards may transfer into the final product. We provide training, document reviews, and customized audits — including GMP visual standards and HACCP process studies — to help you identify risks and put controls in place.

Building Trust with Consumers

At the point of sale, trust in product safety is often the deciding factor. By ensuring safety and compliance, you not only protect consumers but also give your brand a competitive edge.

Our Global Food Contact Material (FCM) Services

- Microbiological testing via our international laboratory network

- Product design HACCP assessments

- Good Manufacturing Practices (GMP) services:

- Visual standard document assessment

- Manufacturing plant audit

- Training programs

- Manufacturing process HACCP assessment

- TÜV Rheinland GMP assessment

Why Partner with TÜV Rheinland?

Food safety hazards in FCMs or production lines can cause severe harm to consumers and serious damage to your brand. The industry has a legal and moral duty to minimize these risks.

By working with us, you gain:

- Proven microbiological testing services during design and manufacturing

- Global lab and expert network to support you anywhere in the world

- Product certification and process assessments that demonstrate due diligence

- Brand value and sales advantage through TÜV Rheinland’s international recognition

Contact Us

Contact us

If you have any questions, please contact our experts.

If you have any questions, please contact our experts.We are willing to provide services to you at any time. Contact us